Key Points to Consider When Selecting an OverWatch® Direct In-Line Pump System

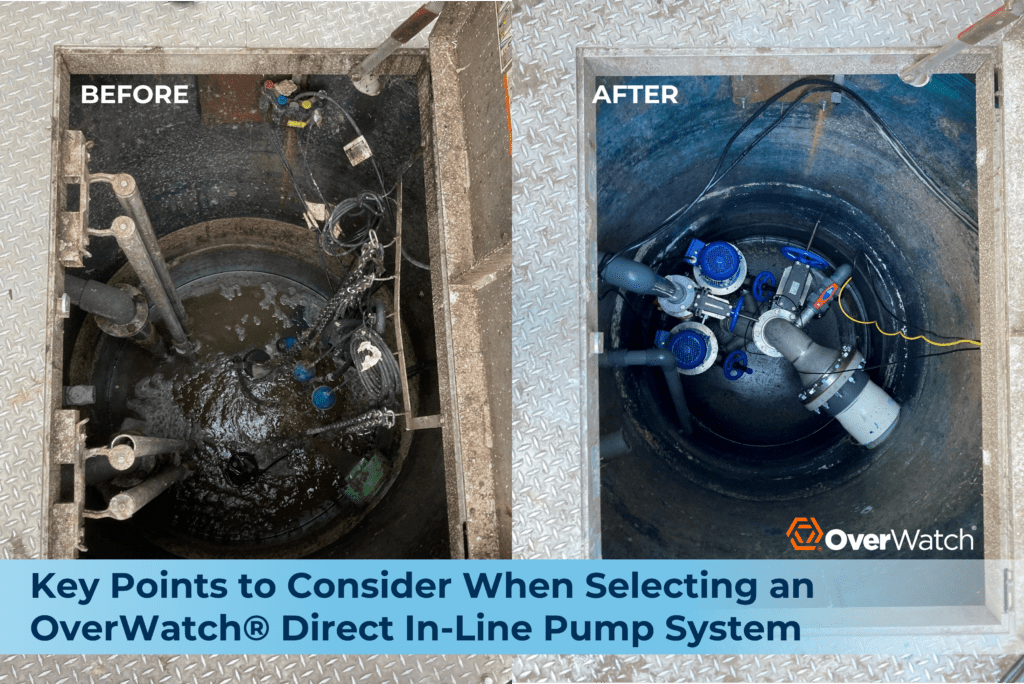

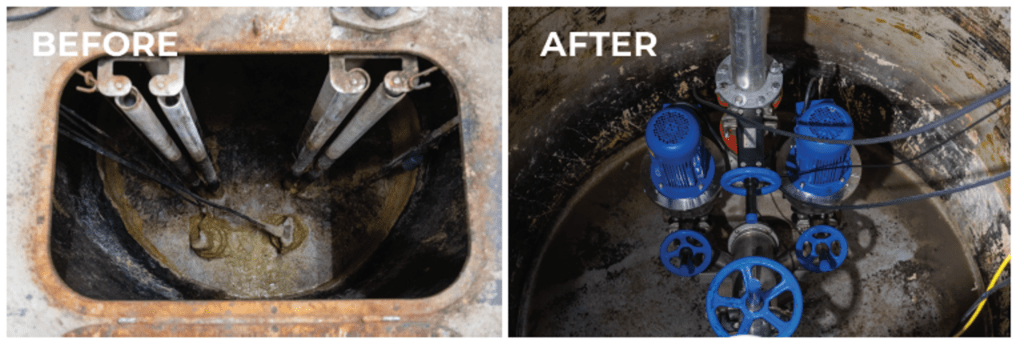

The OverWatch® Direct In-Line Pump System, by Industrial Flow Solutions™, represents an innovative leap in pumping technology. Designed to eliminate the traditional wet well, this system lifts influent right from the point of entry while providing a range of benefits for municipal, industrial, and commercial applications. Whether you’re tasked with reducing odors, improving maintenance routines, or ensuring the longevity of your pumping system, OverWatch® offers an efficient, innovative solution.

Why Choose OverWatch®?

- Smart Sensing for Real-Time Adjustments OverWatch® is equipped with intelligent sensors that adapt to changing conditions, adjusting in real time to manage flow and avoid potential clogs. This results in less downtime, optimized operations, and a significant reduction in system failures, making it an ideal solution for high-demand environments.

- Safer Work Environments One of the most compelling advantages of the OverWatch® system is that it eliminates the need for a wet well. This, in turn, helps create safer working environments for maintenance crews by removing the hazards typically associated with maintaining traditional pump stations.

- Reduced Maintenance and Downtime Clogged pumps can halt operations, costing time and money. OverWatch® eliminates this issue by maintaining efficient, consistent performance. With reduced maintenance needs, the system not only extends the operational life of the pump but also improves overall system efficiency.

- Improved Environmental Impact OverWatch® provides a greener alternative to traditional systems by reducing the need for invasive ground construction. This streamlined installation process lessens the environmental footprint and minimizes the disruption of existing infrastructure.

- Cost Savings By increasing operational efficiency and reducing the likelihood of failures or clogs, OverWatch® contributes to both short- and long-term savings. Its advanced engineering and durable materials result in fewer repair needs, lower energy consumption, and overall improved system performance.

Essential Points to Consider When Selecting Your OverWatch® System

When preparing a quotation or selecting the right OverWatch® system, it’s crucial to understand your project requirements. Below are the key elements to keep in mind:

1. Power Supply and Electrical Requirements

OverWatch® systems are adaptable to a variety of power supply options, ensuring flexibility for different installations. Make sure to confirm the required voltage and phase, such as 230V, 460V, or 575V for 3-phase power, or other specific electrical needs for your setup.

2. Duty Point and Flow Needs

Accurately defining your duty point—such as Total Dynamic Head (TDH), normal flow, and maximum flow—is essential for selecting the right pump. In some cases, you may also need to specify scouring velocities to ensure optimal flow and performance under specific conditions.

3. Hydraulic Body Material and Durability

OverWatch® offers a robust stainless steel body, designed to withstand the toughest environments and harsh materials. Choose between 304L or 316 stainless steel, based on the specific corrosion resistance requirements of your system.

4. Pump Impeller Style

Depending on the system’s size and requirements, OverWatch® provides a range of impeller styles, including DIPCUT, vortex, and channel impellers. Your choice of impeller affects efficiency and solids handling capabilities, with channel impellers providing higher efficiency for larger systems.

5. Certifications and Compliance

If your installation requires specialized certifications, OverWatch® can accommodate various standards, including IP67, CSA, and explosion-proof ratings. Ensure you specify any necessary certifications to comply with regulatory requirements.

6. Control Panel Options

The OverWatch® control panel comes with a variety of customizable features to meet the needs of your project. Enhance the safety and functionality of your system by choosing from options like standard keypads or intuitive touchscreen interfaces to ensure the safety and functionality of the system.

7. Remote Monitoring and Alerts

OverWatch® can be equipped with remote monitoring features like BACnet, Modbus, and auto-dialers, allowing for real-time tracking and automatic fault detection. This enhances system reliability and allows for immediate response to operational issues.

8. Backup Power and Generator Connection

To prevent system failure during power outages, you can integrate a backup generator with your OverWatch® system. Specify the connection type to ensure seamless operation, even during emergency conditions.

9. Customization for Retrofit Installations

OverWatch® systems can be customized for retrofit installations, including hatch dimensions, wet well sizing, and force main requirements. Provide detailed site maps, elevation plans, sump dimensions, and invert height and location to ensure a proper fit within your existing infrastructure.

Additional Equipment and Optional Features

OverWatch® systems can be upgraded with additional equipment, including sump pump kits, flow meters, wall flanges, and temperature-responsive panel heating and cooling solutions.

By considering these key points when selecting an OverWatch® Direct In-Line Pump System, you’ll be well-equipped to make informed decisions that enhance efficiency, reduce costs, and create safer environments for maintenance crews. If you’re ready to move forward with a quote or need further assistance with specifications, the OverWatch® team is ready to help.

For further assistance, don’t hesitate to reach out to your local distributor and discuss your unique project needs.