Smarter Motor Control: Unlocking the Power of the PowerMonitor™

Across water, wastewater, HVAC, mining, and industrial operations, electric motors power critical processes. But while motors do heavy lifting, many maintenance and operations teams are still in the dark when it comes to monitoring their actual performance — until something fails.

That’s where Industrial Flow Solutions’ PowerMonitor™ changes the game.

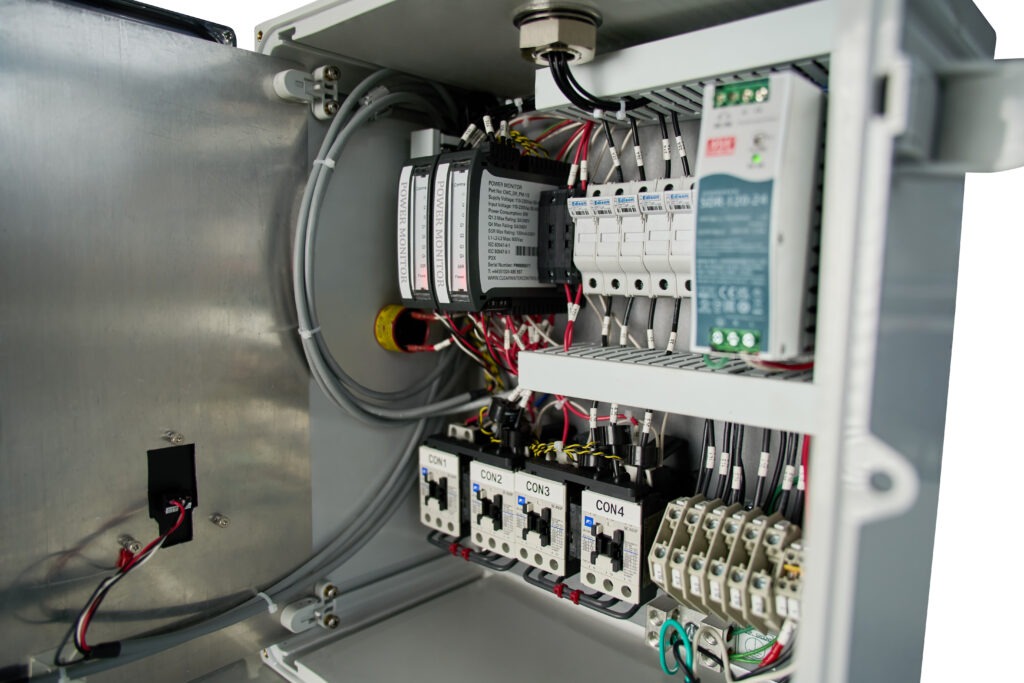

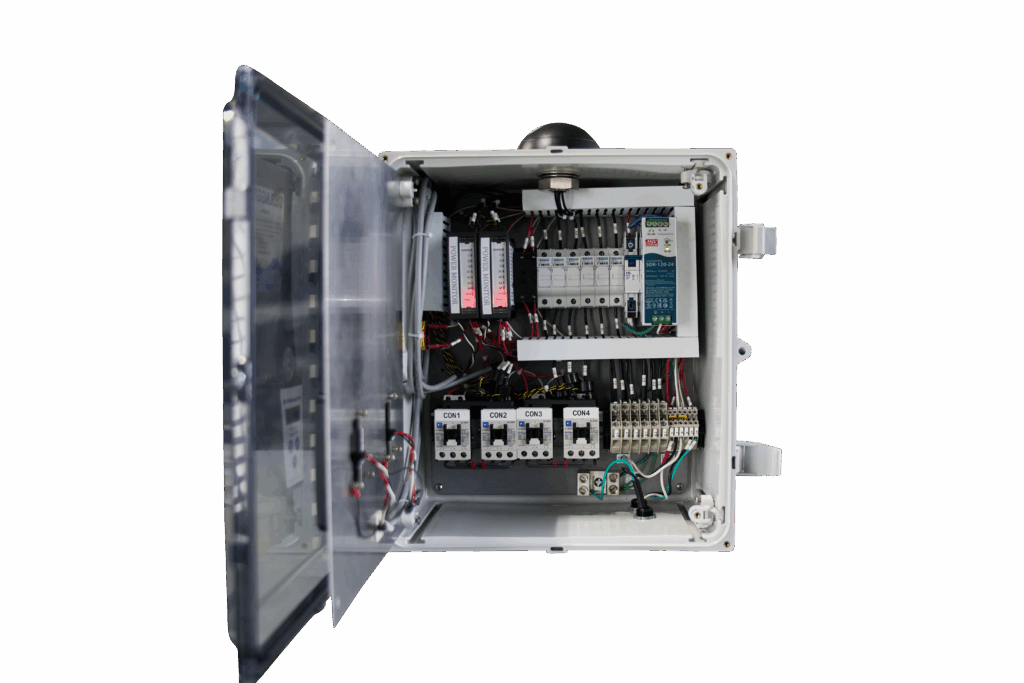

More than just a relay, meter, or vibration sensor, the PowerMonitor™ is an all-in-one motor monitoring, protection, and control device that delivers actionable insights in real-time. Compact and adaptable, it’s designed to fit into virtually any motor-driven system — and give you complete visibility before small issues turn into expensive breakdowns.

Versatility in One Box, Accessible How You Want

The PowerMonitor™ offers flexible installation options and multiple ways to interface with your data — making it ideal for everything from single pumps to complex, multi-motor networks.

How You Can Access and Control:

- Stand-Alone Interface – Quickly connect via laptop for real-time motor diagnostics and data access.

- Advanced Keypad System – Mounts on a control panel for at-a-glance system status, event history, and on-site adjustments.

- Pro Controller Touchscreen HMI – A powerful interface that can integrate with up to 16 PowerMonitor modules, allowing complete station-level visibility, configuration, and trend analysis.

– With no programming or extra tools required, the Pro Controller makes commissioning quick and straightforward.

– Each PowerMonitor comes with expandable I/O as needed.

Whether you prefer hands-on, on-site access or remote diagnostics, the PowerMonitor™ gives you the control you need — without complicating your workflow.

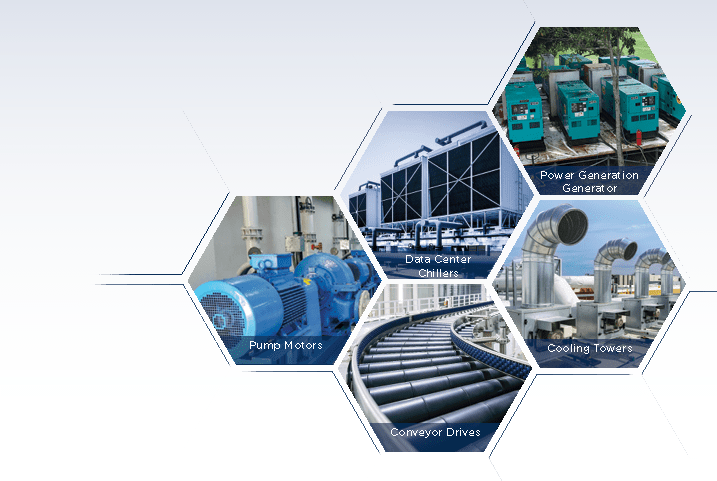

Monitoring for Any Industry

Originally designed for the demanding needs of wastewater systems, the PowerMonitor™ has proven its value across a wide range of industries:

- Water & Wastewater Utilities: Perfect for pump stations, booster pumps, and process controls.

- Industrial HVAC & Data Centers: Keep fans, chillers and compressors running with performance visibility that allow you to learn of issues before they take place

- Oil & Gas: Monitor critical rotating equipment under harsh conditions

- Mining & Process: Protect conveyors, crushers and other essential drive systems in the harshest conditions

Real-Time Alerts. Long-Term Savings.

The PowerMonitor™ goes beyond monitoring — it actively protects your equipment and delivers early warning of potential failures. This results in reduced unplanned downtime, faster troubleshooting, and more optimized maintenance planning.

Motor protection: Against phase loss, thermal overload, over/under current, and more

Condition monitoring: Tracks deviations from average performance to predict failure

Historical Data Logging: Stores up to 170 timestamped alarms/events and up to 20 years of performance data for root cause analysis and compliance

The result?

- Faster diagnostics.

- Lower maintenance costs.

- Less unplanned downtime.

- And a quicker return on investment through real, measurable OPEX savings.

Smarter Motor Control Starts Here

The PowerMonitor™ is more than just a device – it’s a new approach to how you monitor, protect, and control your most valuable assets. Whether you’re managing one pump or an entire network of rotating equipment, the PowerMonitor puts you in control — and it delivers OPEX savings that pay for itself.

Explore more at flowsolutions.com/products/power-monitor or contact our team to configure your setup.