Anti-Ragging Technology

Monitor | Protect | Control

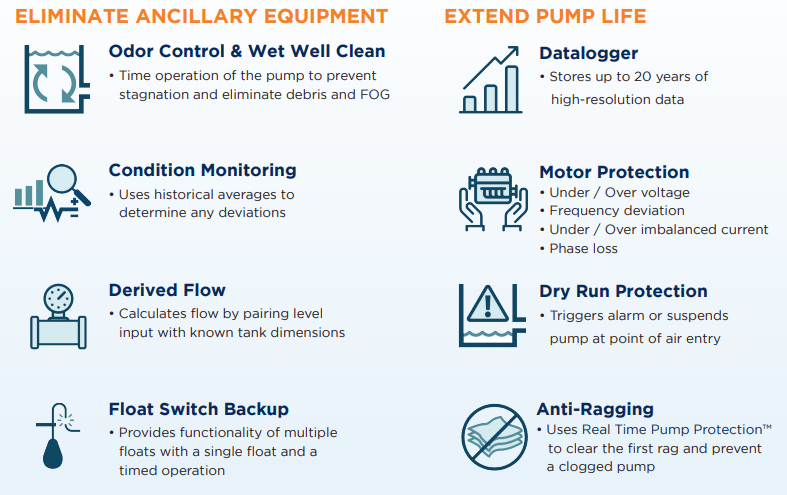

The DERAGGER® is a leading product in the municipal industry, designed to eliminate ragging and clogging issues in pump stations. Available in four models, it offers real-time detection of early rags and clogs, providing intelligent data monitoring and analytics tailored to specific applications. By enabling Real Time Pump Protection™ DERAGGER can

slow, stop, and clean your pump the instant any obstruction impedes operation.

This technology can be applied to pumps, blowers, mixers, or any rotating equipment–and across all motor starter types. Energy savings and increased efficiency are easily achieved

using DERAGGER’s intelligent pump & equipment controlling and optimization tools.

Key features include:

- Dynamic Torque Monitoring™ – Real-time monitoring of dynamic torque waveform to prevent pump clogging.

- High-resolution power analyzer for remote insight into pump station operations.

- Cost savings in time and maintenance through streamlined applications.

- DERAGGER Pro simplifies pumping system controls without requiring PLC or integrator, facilitating easy integration into new or existing panels.

- Modular approach ensures compatibility without redesigning control panels.

- Backed by Industrial Flow Solutions with industry-leading lead times, personalized customer service, and technical support.

For more detailed information, you can download the full product line brochure.

Product Software Downloads:

Virtual Communication Port Drivers – DERAGGER Keypad

DERAGGER Configuration Tool Software

RIO Configuration Tool Software

Available DERAGGER Applications:

The DERAGGER® installation in Palestine, Texas USA, was featured on KLTV news channel. In this feature, learn how “flushable” wipes were plaguing a wastewater plant in Palestine, Texas. After years of research, the city installed three DERAGGER® systems, one for each pump at the plant, to eliminate the clogging and ragging pumps.

Watch the video below to learn more and read the full case study.

Reduced Capital & Maintenance Costs:

- Efficiently operating assets experience less strain, requiring reduced maintenance and having extended lifespans.

- Detects rag interference in equipment, addressing a pervasive issue in the wastewater industry.

- Decreased operational times lead to prolonged pump longevity.

Reduced Labor Costs:

- Eliminates the need for manual cleaning of pumps clogged with rag balls.

- Enables predictive maintenance, optimizing network management.

- Reduces travel time to and from sites for repairs.

- Minimizes risk to operators from handling pumps and raw sewage.

Reduced Energy Costs:

- Clean-running pumps consume less power.

- Optimized performance of all assets significantly reduces run-times.

- Decreased urgent travel to and from sites results in fewer miles traveled.

Industries and Applications

Municipal

Lift stations and wastewater treatment facilities

Industrial

Food, beverage, and pharmaceutical processing

Commercial

Hotels, hospitals, correctional facilities, universities, and residential complexes

Featured Products

DERAGGER+™

- Effortless Blockage Removal

- Advanced Diagnostic Capabilities

- Rapid Return on Investment

- Environmental Impact Reduction

- Seamless Integration

- Real-time Monitoring

DERAGGERLite™

- DERAGGERLite™ anti-ragging device will eradicate pump clogs in wastewater pumps

- Reduces spills and polluting incidents

- Minimal interruption to ‘live’ sites

DERAGGERPro™

- Modular interface for DERAGGER+ and supported accessories

- Increases energy efficiency and reduces cost

- Easily commissioned through color touch screen HMI

PowerMonitor™

- Robust power analyzer and data logger combined.

- Can be installed into existing or new panels

- Easy-to-use keypad has USB connectivity and convenient SD Card data storage

Case Studies

array(7) {

["id"]=>

int(5434)

["gated"]=>

bool(false)

["title"]=>

string(105) "DERAGGER® – Eliminating Pump Lifting Saves South Jordan Pump Station Over $9,000 in the First Year"

["excerpt"]=>

string(230) "The South Jordan Pump Station installed four DERAGGER® systems and keypads in 2016. By enabling Real Time Pump Protection™ to detect rags and run a clean cycle, DERAGGER® clears the first rag and prevents a clogged pump."

["show_full_excerpt"]=>

bool(true)

["url"]=>

string(69) "https://flowsolutions.com/resources/jordanbasinut_deragger_casestudy/"

["download"]=>

string(129) "https://flowsolutions.com/wp-content/uploads/2023/09/DERAGGER-Jordan-Basin-UT-Water-Reclamation-Facility-Case-Study-01.2025-1.pdf"

}

DERAGGER® – Eliminating Pump Lifting Saves South Jordan Pump Station Over $9,000 in the First Year

The South Jordan Pump Station installed four DERAGGER® systems and keypads in 2016. By enabling Real Time Pump Protection™ to detect rags and run a clean cycle, DERAGGER® clears the first rag and prevents a clogged pump.