PROBLEM:

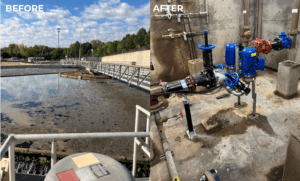

A large municipality in Georgia faced significant issues with clogged air-operated diaphragm (AOD) pumps at its 320MGD wastewater treatment plant. The original system had three AOD pumps at each of the eight scum houses, totaling 24 pumps designed to move scum and debris off the surface of the secondary clarifiers.

However, these pumps were frequently clogged by the scum and debris, and during power outages, additional issues arose when the solenoid valve—responsible for controlling the water fed into the pumps—became out of sync, resulting in more downtime. As a result, the city spent considerable time, labor, and money on unscheduled maintenance at least 4 times weekly.

This ongoing maintenance eventually led to the pumps stopping completely, causing a buildup in the piping and the formation of a solid layer on the clarifiers. The plant needed a reliable pump system that could handle dirt, grit, & debris while maintaining optimal performance, even during power outages.

SOLUTION:

To address these challenges, a duplex OverWatch® system was installed to manage the scum layer for the two clarifiers. This new system eliminated the clogging issues, improved operational efficiency, and significantly reduced costly maintenance events.

The system was designed with elongated legs to fit within the existing footprint, and the control panel was equipped with dry contacts to enable solenoid valve operation using a mechanical timer, solving the power outage synchronization issue.

Several key adjustments were made to increase the pump’s efficiency, including modifying the minimum frequency to prevent deadheading, increasing ramp-up speed to avoid airlock issues, setting the pumps to operate in a linear on/off mode due to infrequent flow, and adjusting the scaling of the level sensor for accurate liquid level readings.

Since the installation of the OverWatch® system, there have been zero maintenance events, the scum layer on the secondary clarifier was eliminated, and the solenoid valve time disruption due to power outages was eliminated. Additionally, operator labor time has increased, allowing staff to focus on more critical plant processes. As a result of this success, seven additional OverWatch® systems are now being installed throughout the wastewater plant.