Annual Cost Savings: $14,820

PROBLEM:

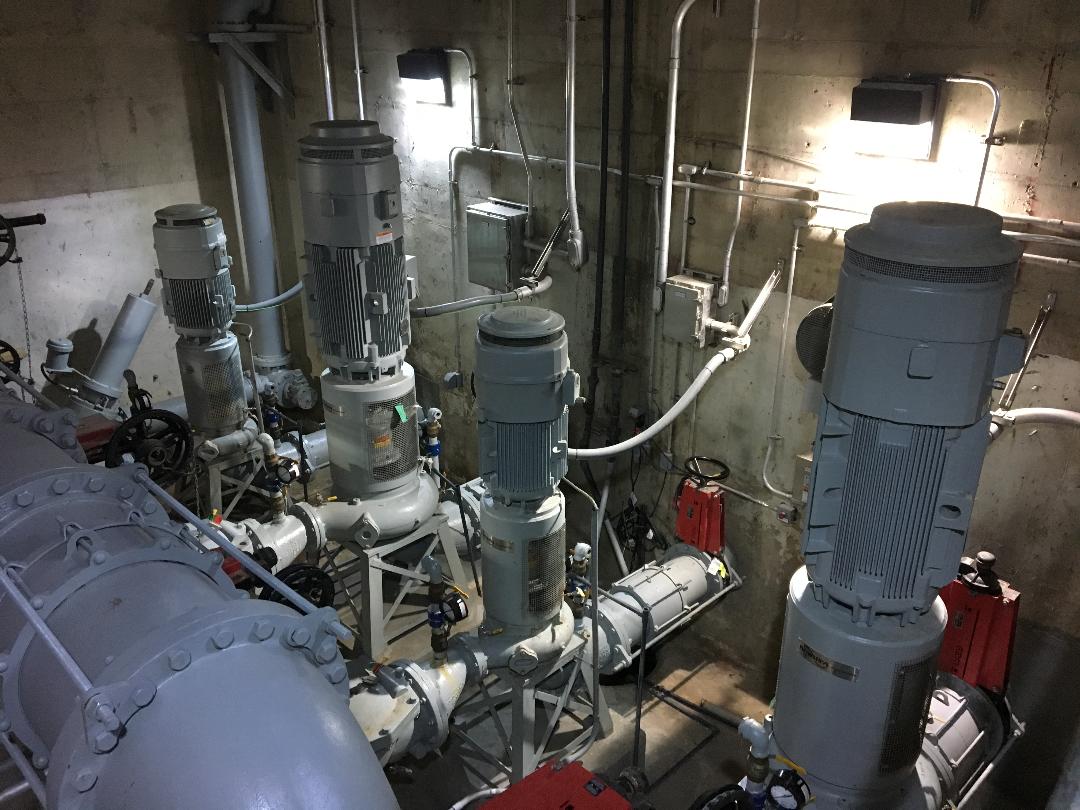

The pump station in Half Moon Bay, CA, which serves a population of 13,000 residents, operates with a 25 HP, 460V, 3-phase pump. This facility suffers from frequent ragging, a problem caused by the disposal of non-woven and fibrous materials. As a result, pumps clog approximately twice a week, requiring 45 minutes to an hour for each cleaning session. This issue not only diverts staff time away from other important tasks but also poses safety risks to employees due to exposure to untreated wastewater and potential sharps.

The persistent ragging problem leads to inefficiencies, as pumps running with rags on the impeller experience reduced flow rates, increased run times, and higher power consumption. This deviation from optimal performance affects the station’s overall

efficiency and leads to higher energy bills. While installing chopper or grinder pumps could mitigate the ragging problem, these solutions bring their own set of challenges. They can increase maintenance costs and potentially cause downstream issues at the treatment facility, where small particles from grinding might complicate the screening process.

SOLUTION:

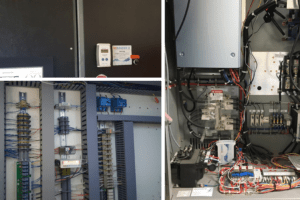

To address the persistent ragging problem, the Sewer Authority installed the DERAGGER® anti-ragging device. This system uses Real Time Pump Protection™ technology to detect and manage rag buildup before it causes significant clogs. By monitoring the power signature of the pump’s motor and adjusting the pump’s behavior, the DERAGGER® allows rags to pass through the impeller and be removed by downstream screens, preventing full obstructions.

The installation of the DERAGGER® led to a complete reduction in ragging, resulting in substantial savings. The authority calculated monthly savings of $735 in labor costs, as staff no longer needed to perform constant pump cleanings. Energy usage decreased by 19%, translating to a $500 monthly reduction in PG&E bills. Overall, these improvements projected an annual cost saving of $14,820 for the sewer authority.

The new system not only enhanced operational efficiency but it also improved staff safety and extended the lifespan of pump components by reducing wear and tear. The technology’s ability to detect early signs of equipment issues allows for timely maintenance, further contributing to the authority’s cost savings.