Problem:

The Village of Sherman, a rural community in western New York with a 40-year-old, 140,000 GPD design package wastewater treatment plant, faces several challenges with its existing lift station. The station, which uses centrifugal pumps to move effluent to the plant head works, struggles with frequent pump clogs caused by mop rags accumulating in the wet well. This results in disruptive shutdowns for repairs and requires weekly cleaning of bar screens and quarterly septic tank servicing. Additionally, the 20-foot deep, 36-inch diameter silo poses significant safety risks, as confined space entry gear is needed for maintenance. The combination of these issues leads to costly maintenance repairs, operational interruptions, and ongoing safety concerns.

After much research, the OverWatch® Direct In-Line Pump System was installed to address the problems effectively, leading to trouble-free operation and significant labor decrease.

Solution:

The OverWatch® system addresses the town’s inflow and infiltration (I&I) issues by integrating two 15hp pumps, each capable of handling 100% of the normal flow in a clean, dry pit.

Designed to prevent frequent clogs, the system features a DIPCUT® impeller with Variable Frequency Drives (VFD). When the impeller encounters obstructions, the VFD detects increased torque and reverses the pump, exposing cutting knives that shred and remove materials like mop rags and fibrous debris. This self-cleaning feature eliminates confined space entry, reduces maintenance costs, increases operational efficiency, and improves access to equipment.

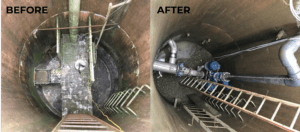

The OverWatch® system was installed in just 11.5 hours, transforming the wet well into a dry pit without requiring liquid volume retention. The installation has eliminated clogs in the pit and bar screens, saving the town on labor and cleaning costs while improving safety and cleanliness for employees.

Costs Eliminated per year: $8,480

- Quarterly Vacuum Truck – $1,760

- Weekly manual cleaning of screens – $1,920

- Weekly manual pump unclogging – $2,880

- Preventative Maintenance – $1,920

“One pump can handle 100 percent of our normal flow. It’s nice to know we have plenty of pump power, especially since we have an I&I issue. When we get heavy rains or thaws, we have enough capacity without any problem,”

– Jay Irwin, Chief Operator, Village of Sherman Wastewater Treatment Plant

Check out the testimonial video from Jay Irwin.