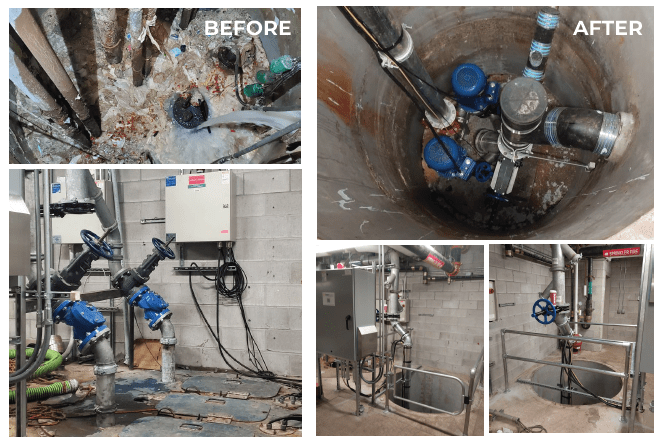

A Boston hospital faced persistent operations interruptions with its wet well sewage ejector system. The hospital implemented an OverWatch® Direct In-Line Pump System, to eliminate the wet well.

PROBLEM:

Boston hospital faced persistent operations interruptions with its wet well sewage ejector system.

Key challenges included:

- Constant Clogging & Service Interruptions: “Flushable” wipes, hospital gowns, & medical debris in the waste stream regularly caused failures.

- Health & Safety Issues: Accumulated sewage resulted in foul odors & hazardous gases.

- Sanitation Concerns: Exposed wet well attracted rodents & other pests.

- High Maintenance Costs: Frequent emergency service repairs, cleanup, equipment replacement and pest control.

- Infrastructure Damage: Prolonged exposure to H₂S accelerated corrosion on the pump system.

The hospital required a reliable, low-maintenance solution for uninterrupted operation.

SOLUTION:

The hospital implemented an OverWatch® Direct In-Line Pump System, to eliminate the wet well.

The installation offered several benefits:

- Elimination of the Wet Well: Lifting influent directly from the gravity invert, prevents the accumulation of sewage and eliminating odors.

- Reduced Clogging & Maintenance: OverWatch® keeps effluent in motion, preventing debris buildup. The patented DIPCUT® impeller reverses when high torque is detected, clearing clogs to ensure reliable operation.

- Improved Sanitation & Pest Control: By removing the exposed wet well, OverWatch® eliminates conditions that attract rodents and pests.

- Preventative Infrastructure Damage: Durable stainless-steel construction withstands harsh wastewater conditions & corrosion.

OverWatch® transformed the hospital’s wastewater system, addressing operational issues while improving efficiency, hygiene, and cost-effectiveness.