Solids Handling Pumps

Solids Handling Pumps

From shopping centers to wastewater management facilities, clogs are never a good thing. With solids handling submersible and non-submersible pumps from Industrial Flow Solutions™, you don’t need to worry about a clog delaying a workday or dismaying a customer.

Solids handling pumps help pass solids, trash, and stringy material, often with the assistance of an impeller or a dedicated cutting/shredding/grinding mechanism. These pumps allow for easy pumping and transporting of fluids mixed with a concentration of solids. Industrial Flow Solutions specializes in the design, manufacturing, sales, & service of solids handling submersible pumps to a wide range of industries including municipal water & wastewater, food & beverage, commercial buildings, and more.

What Is A Solids Handling Pump?

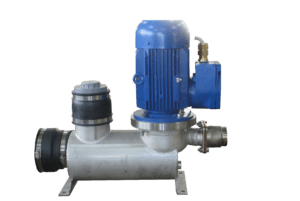

Solid handling pumps – also known as solids handling shredder pumps or solids handling slurry pumps – are constructed of durable stainless steel or cast iron with oil-filled motors. These no-clog systems mean no downtime from a clogged pump, reduced maintenance, and no debris or trash removal. Solids handling pumps are available with up to 30 horsepower and are frequently fitted with a shredding impeller, that can break, shred, and rip solids to pieces.

Solids Handling Pump Models:

- Grinding

- Non-clog/Passing

- Shredder

- Vortex

Solids Handling Pump Applications

Industrial Flow Solutions manufactures and sells solids handling pumps to businesses ranging from commercial to industrial. These pumps are also frequently used in municipal wastewater processing as well as residential complexes.

- Storm & Wastewater Management

- Influent/Effluent Removal

- Wastewater processing

- RAS/WAS Sludge

- Lift/Pump Stations

- Pharmaceutical & Medical Facilities

- Hotels

- Correctional facilities

- Universities

- Residential Complexes

- Food Processing Plants

- Chemical Waste

- Paper Mills

- Amusements Parks

- Campgrounds

- Schools

- Sports Centers

Solids Handling Pump Can Process:

- Heavy solids-laden liquids

- Fats, oils, greases

- Solids up to 3.5 inches

- Plastics and light metals

- Food waste

- Fibrous solids

Solids Handling Pumps at Industrial Flow Solutions

At Industrial Flow Solutions, we’ll work with you to find the perfect solids handling pump for your system. Consideration is given to the type of material most often passing through your pipes as well as the number of service hours needed each day.

Featured Products

OverWatch – Single Pump

OverWatch® Direct In-Line Pump System

- Patented system lifts effluent directly at point of entry

- Patented impeller/shredder cuts fibrous materials and other solids

- Variable Speed Drives for continuous modulated pumping directly from the effluent inlet to save energy

SKF Series

- Fahrenheit® HIGH TEMPERATURE, solids-handling, non-clog pump

- Solids handling <3.5”

- 304 stainless steel

LX Series

- Heavy-duty non-clog wastewater pump

- Non-clog, cast iron single channel impeller

- Large 3″ solid passage

Case Studies

array(7) {

["id"]=>

int(1263)

["gated"]=>

bool(false)

["title"]=>

string(90) "Boiler Blowouts: Renewable Energy Plant Uses BJM KBF Series Hi Temp Slurry Pump-Case Study"

["excerpt"]=>

string(879) "Boiler Blowouts: Renewable energy plant installs hi-temp slurry pumps to eradicate pump failures. Covanta Energy is one of North America’s largest owners and operators of waste-to-energy plants and other renewable power facilities. Their 60+ facilities produce electricity for about one million homes. The Covanta Dade energy plant in Florida processes 4,200 tons of municipal solid waste and biomass fuel daily. The plant burns that waste to produce electricity, boiling water to turn turbines that generate 77 megawatts of power. During the boiler blowout procedure, 185°F water is pumped from the system to minimize buildup of scale and corrosion. Read about Covanta engineers' pump solution that could stand up to 185°F water, was resistant to corrosion and abrasive sand and grit, and a pump that was available with the high head option needed for the application."

["show_full_excerpt"]=>

bool(false)

["url"]=>

string(143) "https://flowsolutions.com/resources/boiler-blowouts-renewable-energy-plant-installs-hi-temp-slurry-pumps-to-eradicate-pump-failures-case-study/"

["download"]=>

string(117) "https://flowsolutions.com/wp-content/uploads/2020/09/IFS-RenewableEnergyPlantHiTempSlurryPump-KBFSeries-CaseStudy.pdf"

}